1.PURPOSE OF THE PROVINCE TESTING

Static compression test is conducted before construction Pile to determine the bearing capacity of piles, data on strength, deformation and load-displacement relationship of piles as a basis for designing or adjusting design projects, selecting equipment and tools. suitable construction technology.

2.PRINCIPLES OF US EXPERIMENT

The test is carried out by using a static load to press the pile axis so that under the action of the pressure, the pile sinks deeper into the ground. Loading on the pile head is carried out by hydraulic jacks with the reaction system being the loading platform, anchoring or a combination of both. The data on load, displacement, deformation, ... obtained during the experiment is the basis for analysis and assessment of the load capacity and the load-displacement relationship of the pile in the ground.

3.NUMBER OF TEST STEELS

Due to design regulations, it is normally taken to be equal to 1% the total number of piles of the building but in all cases not less than 02 piles.

4.EXPERIMENTAL EQUIPMENT US

Experimental equipment includes:

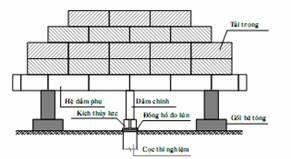

Decorative: Used in the static compression test of piles at the construction site are precast concrete counterweights arranged in blocks on a steel supporting beam system.

Maximum total load : 120% Maximum test load

Support beam system: As a reinforced steel frame system, calculated and fabricated enough to withstand the maximum test load Pmax = 300 tons. The main bearing girder is 01 box girder made of 400 mm high steel, reinforced with box. The auxiliary beam system is a high steel beam system - I500mm placed on the support system. This beam system is reinforced and does not deform under load as well as during the test.

Support system: Is a system consisting of many precast reinforced concrete loads of different sizes and loads (ton) is different enough to support the experimental counterweight system placed on the ground to support the loaded beam system. The bearing system is calculated with enough cross-section to ensure that it does not cause settlement when the load is applied for the test, and does not affect the working of the pile as well as other equipment during the test.

Load system: Is a system consisting of many precast reinforced concrete loads of different sizes and loads (ton) is different, the test counterweight is placed on the sub-beam system so that it is balanced. Counterweight load is calculated according to the requirements set forth for each type of pile and the required design load.

Loading system:The experimental load system in the project uses hydraulic jacks with a lifting capacity greater than ≥ 150% with the largest test load, hydraulic jacks are tested and certified by functional units. This jacking system is placed on the top of the test pile, the axis of the hydraulic jack coincides with the axis of the test pile, the jacking system and the transmission beam ensure the transmission of the load at the center of the test pile. (see the appendix of the certificate of inspection of the hydraulic jack)

Force measuring system:Force measuring system using hydraulic meter with measuring load 0-600 kg/cm2. The compressive force acting on the test pile head is calculated through the readings of the pressure gauge and the lifting coefficient of the hydraulic jack, which is tested and certified by functional units. (see the appendix to the Certificate of Inspection of Pressure Gauges)

Hydraulic pump system: The hydraulic pump system is attached to the hydraulic jack with the oil supply pipes to the jack to adjust the jack's lifting capacity as desired, the pump flow is 3 liters/min, the maximum pressure is 600 kg/cm2.

Displacement measuring system: Including 04 settlement gauges with a maximum measuring range of 50mm with an accuracy of 0.01mm, which are fastened to the test pile body through a magnetic support system and steel shackles, which are tested and issued by functional units. accreditation. (see the appendix of the Certificate of Inspection of the Timer 04 pieces)

Displacement meter mounting system: Is a support system with magnetic legs by permanent magnet, fastened to the steel shackle system mounted on the top of the test pile.

Standard beam system: standard girders, also known as metering bridges, have sufficient rigidity and are not affected by weather shocks (can be box girders, U, I, V beams), the distance from the foot of the bridge supports. clock, datum to the center of the test pile is not less than 3D

Standard landmark system: The standard landmark system used for the construction is a sectional steel system buried in the ground. The hardness of the reference bar ensures no deformation during the test and is not affected by external influences.

5.EXPERIMENT PREPARATION US

The piles being tested should be checked for quality according to current standards for pile construction and acceptance.

Static compression testing is conducted for piles that have had enough time to recover the structure of the soil damaged during construction or the concrete reaches strength. For prestressed reinforced concrete piles, rest time from completion of construction concrete pile pressing until the experiment is 07 day. For bored piles, the rest time from completion of construction to testing is 21 day.

The test pile head can be cut or added, but must meet the following requirements:

– The distance from the pile end to the main girder must be sufficient to install jacks and measuring devices;

– The pile head face is made flat, perpendicular to the pile axis, if necessary, additional reinforcement is required so as not to be damaged locally under the experimental load;

– Measures should be taken to eliminate the friction of the pile part higher than the foundation bottom reinforcement if it is considered that it may affect the test results.

The jack must be placed directly on the pile head pad, centered relative to the center of the pile. When using multiple jacks, jacks must be arranged so that the load is transmitted axially, centered on the pile head.

The pile head clamp is fastened to the pile body, approximately 0.5 diameter or width from the pile head.

The standard beams are placed parallel to both sides of the test pile, the beam supports are firmly buried in the ground. The displacement meter is mounted symmetrically on either side of the pile head and is stably mounted on the reference beams, the base of the displacement meter is supported on the pile head clamp or the pile head pad (or vice versa).

The installation distance of equipment is specified as follows:

– From the center of the test pile to the center of the anchor pile or the ground anchor wing is larger than 3D but in all cases not less than 2m;

– From the test pile to the nearest point of the supports larger than 3D but in no case less than 1.5m;

– From the test pile to the standard beam supports not less than 1.5 m;

– From the reference point to the test pile, the anchor and the bearings are loaded with loads larger than 5D but in all cases not less than 2.5m.

6.EXPERIMENTAL PROCEDURES

Before conducting the test, the experimenter preloads to check the operation of the equipment and creates contact between the test pile head and the test device. Preload with 5% of design load, hold the load for 10 minutes then reduce the load to 0% level, adjust the displacement gauges to the load level 0%.

TABLE OF EXPERIMENTAL PROCEDURES US

|

Load level experiment |

Time to maintain test load to the top of the test pole |

Time to monitor and record experimental data |

|

5% |

Hold for 10', to eliminate deformation caused by loading. | |

|

0% |

Record the initial data. | |

|

25% |

Minimum is 1 hour and achieve the conventional stable settlement of 0.25 mm/hr, but not more than 2 hours. | Record the results at the time: 0; ten'; 20'; 30'; 45' and 60'. |

|

50% |

Minimum is 1 hour and achieve the conventional stable settlement of 0.25 mm/hr, but not more than 2 hours. | Record the results at the time: 0; ten'; 20'; 30'; 45' and 60'. |

|

75% |

Minimum is 1 hour and achieve the conventional stable settlement of 0.25 mm/hr, but not more than 2 hours. | Record the results at the time: 0; ten'; 20'; 30'; 45' and 60'. |

|

100% |

Maintain in 06 o'clock and reach the conventional stable settlement. | Record the results at the time: 0; 10',20'; 30'; 45', 60'; 120' and continue 60' at a time until the allotted time has elapsed. |

|

50% |

30 minutes |

Record the results at the time: 0 ; 10', 20' and 30'. |

|

0% |

60 minutes |

Record the results at the time: 0 ; ten'; 20'; 30'; 45' ;& 60' |

|

25% |

30 minutes |

Record the results at the time: 0, 10', 20' and 30'. |

|

50% |

30 minutes |

Record the results at the time: 0, 10', 20' and 30'. |

|

75% |

30 minutes |

Record the results at the time: 0, 10', 20' and 30'. |

|

100% |

30 minutes |

Record the results at the time: 0, 10', 20' and 30'. |

|

125% |

Minimum is 1 hour and achieve the conventional stable settlement of 0.25 mm/hr, but not more than 2 hours. | Record the results at the time: 0, 10', 20' and 30', 45' and 60'. |

|

150% |

Minimum is 1 hour and achieve the conventional stable settlement of 0.25 mm/hr, but not more than 2 hours. | Record the results at the time: 0, 10', 20' and 30', 45' and 60'. |

|

175% |

Minimum is 1 hour and achieve the conventional stable settlement of 0.25 mm/hr, but not more than 2 hours. | Record the results at the time: 0, 10', 20' and 30', 45' and 60'. |

|

200% |

Maintain in 24 hours and reach the conventional stable settlement, whichever is longer. | Record the results at the time: 0; 10';20'; 30'; 45', 60'; 120' and continue 60' at a time until the allotted time has elapsed. |

|

150% |

30 minutes |

Record the results at the time: 0, 10', 20' and 30'. |

|

100% |

30 minutes |

Record the results at the time: 0, 10', 20' and 30'. |

|

50% |

30 minutes |

Record the results at the time: 0, 10', 20' and 30'. |

|

0% |

1 hour |

Record results at the time: 0', 10', 20', 30', 45', 60' |

Regulation of increase and decrease of load

– Load each level to the maximum expected test load of 200% Ptk with each level of loading equal to 25% of design load. The new load level is only increased when the settlement speed of the pile head reaches the conventional stability (ΔS ≤ 0.25mm) but not more than 2 hours. Hold the maximum load level until the pile head settlement reaches conventional stability or 24 hours, whichever is longer.

– After the end of the loading, if the pile is not damaged, reduce the load to 0, each level of load reduction is equal to 2 times of the load level and the retention time of each level is 30 minutes. than.

Regulations on sabotage, stopping and termination of experiments

- Regulations on destruction of piles

– At the load level less than the maximum test load, the settlement of the pile head increases continuously without increasing the load.

– The pile does not reach the conventional stable settlement after 1 day and night (24 hours) holding the load at any load.

– At any load, the total displacement exceeds 10% pile size.

- Damaged pile material.

– Pile settlement speed at each load level is 5 times larger than the previous load level (sudden increase in settlement).

- The experiment must be stopped if the following phenomena are detected:

– The benchmarks are set incorrectly, unstable or damaged.

– Click does not work.

- The reaction system is not stable.

– The pile head is broken, the compression beam is tilted

- The ground is destroyed.

Testing can be continued after treatment or remediation

- End of experiment

– Achieve the experimental goal according to the outline

- The test pile is damaged.

7. REPORT OF EXPERIMENTAL RESULTS US

Report the results of the pile static compression test carried out according to the standard TCVN 9393:2012, including:

- Explanation of the results report.

- Summary table of experimental results.

- Table of experimental data in the field.

Experimental results charts:

- Load-Displacement relationship diagram.

- Diagram of Transposition – Time

- Load-Time-Displacement Relationship Diagram

- Load-Time relationship graph

- Conclusions and recommendations.

8.TREATMENT AND STRENGTHENCE OF US TEST PILES

– The pile head may have to be cut down or connected to make it reasonable for this work to be handled by the testing contractor to suit the nature of the assigned test work (this depends on the construction site). as well as experimental equipment).

– Sika GP screed to flatten the pile surface

Test the system of experimental equipment, the lifting capacity of the hydraulic jack, the oil pump, the sensitivity and uniformity of the pressure gauge and the displacement gauge. Inspection period of measuring devices and tools.

9. SAFETY WORKS AND FIRE PREVENTION AT THE WORKS

In addition to complying with labor safety regulations in construction, it is necessary to observe the following regulations in the experiment:

- Unauthorized persons are not allowed to enter the testing area.

– Check the safety level of the system of loading beams, supports and supports.

– In the rainy and windy season, the experimental unit must have a tarpaulin to cover the rain

– Because static compression testing is conducted in the field and using heavy equipment, it is necessary to take appropriate safety measures to avoid occupational accidents and damage to machinery and equipment. tested.

– During the experiment, do not allow the operation of other equipment near the experimental area to ensure the safety and accuracy of the data collected during the experiment.

– After the end of the experiment, all experimental equipment should be dismantled, transported from the field and carefully maintained.

– For fire prevention, there are always measures to prevent ignition sources and flammable environments, as well as specific regulations on the use, operation, and maintenance of machinery, equipment, materials and hazardous products. may be a source of ignition. Flammable substances are properly placed and isolated from the flammable environment.

PROFESSIONAL POWER CONSTRUCTION WORKS

CONSTRUCTION OF DRILLING Pile - Rock Drilling

Contact Info:

- Address: No. 12, Street 27, Van Phuc Urban Area, Hiep Binh Phuoc Ward, Thu Duc City, HCMC

- Phone number: 0915.611.337 Mr. Phuong Or 0915.411.337 Mr. Quan

- Email: [email protected] or [email protected]

- Website: Lethycorp.com

- Road Map: See