I. Technology requirements.

1. Concrete.

a) Request for distribution.

- Use commercial concrete grade B20, B25, ...

- Pouring concrete according to the principle of using long pipes (sprung mortar), so according to the proportion of concrete mix, it must also be suitable for this method (concrete has enough plasticity, stickiness, easy flow in the pipeline). For the method of grouting with bentonite solution to help stabilize the wall of the borehole, the concrete pump pipe is always submerged in the concrete, then the rising concrete will slowly push the bentonite solution out of the bored pile borehole.

– Method of concreting bored piles and withdrawing vertical pipes using wall pipes: Used when the geology is weak, the area has surface water in caves.

+ Temporary bulkhead pipe: retracted during the concreting of piles

+ Permanent wall pipe: Leave after construction

Advantages: Good pile quality

Cons: The wall pipe construction machine is bulky and noisy.

- Concrete:

+ Ratio N-XM 50%.

+ Weight of XM 400kg/m3 of concrete.

+ Sand about 45%.

– Reasonable cone slump 181.5(cm) (Usually 13 18(cm)).Concrete delivery must be continuous so that the entire time to concrete one pile is completed in 4h.

– Additives can be used to satisfy the above characteristics of concrete.

– The maximum diameter of aggregate is the smallest of the following dimensions:

+ A quarter of the eyelet of the reinforced cage.

+ Half layer of reinforcement protection.

A quarter of the inner diameter of the concreting pipe.

– It is necessary to choose a commercial concrete factory with modern technology, aggregate and clean water as required. It is necessary to test mix and check the capacity of the plant and the quality of the concrete. Select finished concrete mix and admixtures before batch pouring.

-At the construction site, each commercial concrete truck must be checked for the preliminary quality, the time to start mixing and the time when the concrete is finished, the cone slump. Each pile must take 3 combinations of samples to test the strength. Must have strength test results from a fully legal and independent laboratory.

b) Equipment used for concrete work.

– Commercial concrete is transported by special vehicles.

– Conduits from the hopper to the required depth.

– Hopper to collect concrete from the dump truck connected to the pipeline.

– Pipe and hopper holders.

2. Reinforcing steel.

- Reinforcing steel must be used in accordance with the type and model specified in the approved design, the reinforcement must have the manufacturer's certificate, and the test results of an independent laboratory with full legal expertise. legal entity for each lot before putting into use…

– Reinforcing steel that is processed, forced to build the cage is transported and placed on a rack close to the installation location to facilitate future construction.

– Length of fastening joint is 45d (d- diameter of pile steel), fastening steel has a diameter of 3.2 (mm).

– Steel belt fasteners use one side electric welding joint, welding length 15d. Reinforcing belt steel is welded with bearing steel.

– Edge – edge distance between the reinforcement must be greater than 3 times the coarse aggregate particle diameter of the concrete.

- The reinforcement belt should be placed at the outer edge of the main core, without bending hooks, hooks made according to the requirements of construction technology should not poke inside to affect the operation of the concrete conduit.

– The inner diameter of the steel cage must be 100mm larger than the outside diameter at the connection of the concrete conduit.

– To ensure the thickness of the concrete protection layer, it is necessary to place positions on the main reinforcement bar for each section according to the pile depth.

– According to TCXD 206 – 1998, the error allowed to manufacture reinforcement cage:

3. Bentonite solution.

– In the construction of bored piles, bentonite solution has a great influence on the quality of piles:

+ The level of the solution is low, the supply is not enough, the bentonite is diluted, the water is easily separated, leading to the collapse of the borehole wall, the breakage of the concrete pile.

+ The solution is too dense, the sand content is high, leading to difficulty in pouring concrete, blocking the pouring pipe, large amount of sand deposited at the tip of the pile will reduce the load capacity of the pile.

Effect of Bentonite solution.

+ Make the pit wall not collapse thanks to the solution that penetrates deep into the sand crevices, cracks, and mixes with loose sand to keep the sand and debris from falling and forming an elastic film around it. The wall of the pit keeps water from seeping into the wall.

+ Create a heavy environment to lift up the soil, rock, drilling debris, sand to the top to overflow or suck out of the borehole.

+ Slow down the sedimentation of sand particles, in the state of small particles in suspension to easily handle sediment.

-With the use of bentonite clay mortar, the borehole wall is stabilized by the following two factors:

+ Bentonite solution acts on the borehole wall a value of hydrostatic pressure that increases with depth.

+ The stalactite particles will adhere to the borehole wall and penetrate into the holes on the hole wall to form a thin, waterproof and durable film.

– Therefore, the preparation of enough Bentonite solution of good quality plays an important role in the construction process and the quality of bored piles.

b) Procedure for mixing Bentonite solution.

– Pour 80% calculated amount of water into the mixing tank.

– Pour slowly the amount of Bentonite powder according to the design.

– Slowly pour in the amount of additives if any.

- Continue mixing for 15-20 minutes

– Pour the remaining 20% of water and mix for 10 minutes.

– Transfer the mixed bentonite solution to a container, ready to be supplied to the borehole or mixed with the filtered recovered bentonite solution through a sand sieve to supply the borehole.

The drilling fluid mixing station at the construction site includes:

A bentonite mixer.

+ Some manufacturing equipment ensures the dissolution of Bentonite powder in water

+ One or more storage tanks or silos allowing the site to prepare sufficient reserves to prevent any drilling problems.

+ Some sanitary equipment ensures the separation of large residues by sieve and sand by centrifugal cyclone.

c) Some notes when using Bentonite to construct bored piles.

– Mixing dosage from 30 to 50 kg of Bentonite/m3, depending on water quality.

– Water used: clean water, tap water.

– Supplement for pH adjustment: NaHCO3 or similar.

– Depending on the specific case to achieve the criteria set forth by the regulations, some additives such as Na2CO3 or NaF can be used.

During construction, the surface of the solution in the pile hole must be 1.0m higher than the groundwater level. When there is an influence of the groundwater level up and down, the surface of the solution must be 1.5m higher than the groundwater level. .

– Before pouring concrete, the density of the solution within 500mm from the bottom of the hole must be less than 1.25; sand content 8%; 28s viscosity to easily push to the ground.

– The density and viscosity selected must be suitable for the geological conditions of the works and the method of using the solution.

– In addition to Bentonite solution, CMC can be used, synthetic solution, salt water solution, etc., depending on the geological conditions of the project.

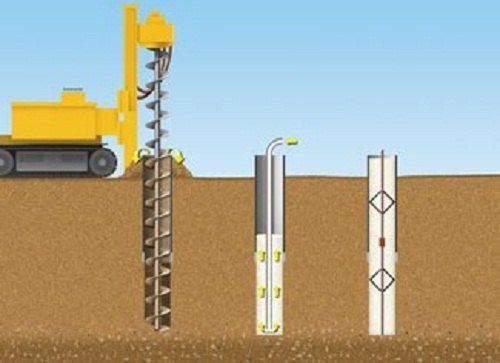

II. Technological process for construction of bored piles by twisting bucket method in bentonite solution using wall pipes.

The technological process of bored pile construction is shown in the order of work according to the diagram:

1.This is an important job that affects the position and distance of the columns of the work, is the job of locating the location of the work from the design drawings to the field.

- Based on the work locating map issued by the chief architect's office or an equivalent agency, establish landmarks of the work. These landmarks must be accepted by the competent inspection agency.

– From the ground to locate the pile foundation, set up a positioning system and control grid for the work according to the X, Y coordinate system. These grids are moved and fixed to neighboring works or incorporated into landmarks. These landmarks are carefully fenced and protected and continuously checked to prevent movement caused by collisions and settlements.

– The borehole and the center of the pile are located before placing the support pipe and then keep the two test markers at right angles to each other and the same distance from the center of the pile.

2. Lower the wall pipe.

– Wall pipe (or strut) made of steel with a large diameter of approximately 100 150mm, we choose 900mm long (2.5 3)d and take 2m, placed in the upper part of the borehole, about 0.6m above the ground. .

- Wall pipes have the following effects:

+ Positioning and guiding the drill to follow.

+ Keep the surface of the borehole stable to ensure that the wall does not collapse on the borehole

+ Protect the borehole so that gravel, rocks and equipment do not fall into the borehole

+ Used as a temporary pouring floor and manipulation for tying, connecting and erecting reinforcement and concrete pipes.

– Wall pipe is recovered after pouring concrete piles.

– The wall pipe is lowered by using the drill itself with a bucket fitted with a cutting belt to expand the diameter. Pre-drill a hole to the depth of the casing, use a crane to expand the diameter, pre-drill a hole to the depth of the casing, use a crane or excavator to bring the bulkhead into position, lower it to the bottom of the work. necessary program. After placing the wall pipe, the wall pipe must be tightly packed with clay and wedges to prevent the wall pipe from moving during the drilling process.

3. Drill holes.

– Because the bentonite solution is of special importance to the borehole, it is necessary to check the quality of the bentonite solution, recovery line, mud pump, filter and backup machines before drilling, and add a conduit to increase solution level and pressure if necessary. Check drilling equipment, cables, excavator buckets, etc. to work continuously to avoid problems occurring while drilling.

– Adjust the horizontality of the drill and the verticality of the drill rod. Determine the coordinates of the drill bucket on the control panel of the drill for quick and accurate operation.

– The drill rod named Kelly Bar has a specially made antenna form consisting of 3 interlocking tubes and transmits rotational motion, the innermost pipe is attached to the drill bucket, the outermost pipe is attached to the rotating motor of the speed drill. rotates from 20 to 30 rpm. Drilling capacity can be achieved from 8-15m3/h. When the bucket is full of soil, the bucket will be pulled up slowly (0.3-0.5m/s). At this speed, it is guaranteed not to cause the piston effect to collapse the borehole wall.

– When drilling beyond the depth of the wall pipe, the borehole wall will be held by Bentonite. Therefore, it is necessary to provide enough bentonite solution to create pressure to keep the borehole wall from collapsing. The solution level must be at least 1-2m higher than the groundwater level.

– When drilling, it is possible to determine the depth of the borehole through the cable reel or the length of the drill rod. For accurate determination, use a plumb with a diameter of about 5cm tied to the end of the tape measure and drop to the bottom to measure and check the depth of the borehole and the height of the concrete during the pouring process. During the excavation process, it is necessary to check the verticality of the pile through the drill rod to ensure that the pile has an inclination of not more than 1%.

– While drilling due to different soil structure and may encounter foreign objects, it requires the drill team leader to have a lot of experience to promptly handle some special tools:

+ Sand, slippery gravel should use bucket bucket.

+ Solid clay should use a bucket to drill the chicken intestine.

+ Young rock, consolidated rock using a combination drill and rock drill.

4. Confirm borehole depth.

– During the design, the designer based on a few survey boreholes to assume and calculate the required average depth of the bored pile. In practice, since the geological cross-section can be uneven between drill bits, it is not necessary to drill to a certain design depth. In fact, the designer prescribes the stratigraphy of the pile bottom and when drilling, it must be submerged into the pile bottom soil layer at least 1 times the pile diameter. To accurately determine this stop when drilling, people take samples for each drill bucket. The field supervisor confirms that the required depth has been reached, takes full notes including taking photos of the report documents for each drill, uses a cleaning bucket to dredge up soil and rocks in the bottom of the borehole and moves on to the next stage. other.

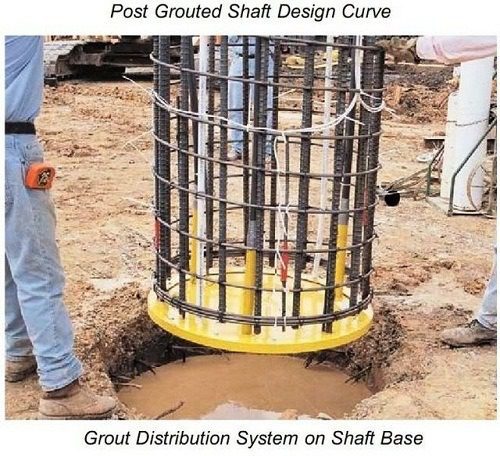

5. Lower the reinforcement.

– The reinforcement is pre-tied into each cage, transported and placed on a rack near the borehole. After checking the bottom of the borehole, if the layer of mud and sand deposited at the bottom of the borehole is not more than 10cm, reinforcement can be installed.

– The reinforcement is lowered into the borehole by cage, temporarily suspended on the mouth of the wall pipe by crossing the pre-tied reinforcement belts, about 1.5m from the top of the cage.

– Use a crane to bring the next cage to the lower cage and continue lowering until it is finished. Reinforcement is fixed to the mouth of the wall pipe through 4 lenses hanging on the mouth of the wall pipe. In case the reinforcement is not placed to the full depth of the pile, it is necessary to resist the buoyant force of the reinforcement when pouring concrete by welding 3 I-shaped steel bars 0120 to the pipe wall to fix the steel cage. In order to ensure the protection layer of longitudinal reinforcement is 10cm, it is necessary to weld additional steel belts outside the steel cage or concrete spacers.

– When lowering the reinforcement, slowly let the reinforcement be vertical and avoid colliding the steel cage into the borehole wall.

6. Install the concreting pipe.

– Concreting pipes are made of steel with a diameter of 25-30cm and are made into sections with a variable length of 2m; 1.5m; 1m; 0.5m to be able to assemble the complex according to the depth of the borehole.

– There are two ways to connect today: threaded connection and cable connection. Cable connection is usually faster and more convenient. Pipe joints have rubber gloves to prevent Bentonite solution from penetrating the concrete during pouring, greased for easy removal.

– Concrete pouring pipes are installed gradually from the bottom up. To be able to install the pipe, a special support system is used with the structure like a steel ladder placed through the mouth of the wall pipe. On the ladder there are 2 hinged half rings. When the two halves of the annular ring collapse to form a cone that hugs the wall of the pipe, the pipe mouth with the larger diameter is trapped on the two halves of the ring and thus the concreting pipe is hung to the mouth of the pipe wall through a special rack. This. The bottom of the pour pipe is placed 20cm from the bottom of the borehole to avoid blockage of the pipe due to the soil and rock at the bottom of the borehole.

7. Treatment of sediment at the bottom of the borehole.

– In wet drilling technology, fine particles suspended in bentonite solution settle down to form a layer of mud, which greatly affects the bearing capacity of the pile tip. After installing the concreting pipe, we measure the depth of the bottom of the borehole again, if the sediment is larger than 10cm, then it is necessary to carry out sediment treatment.

– Method of blowing and washing with compressed air: Using concrete pipe as a sludge treatment pipe. After installing the concreting pipe, the blower head is installed on the top of the pipe, the blower head has 2 doors, 1 door is connected to the 150 pipe to recover the bentonite solution and mud from the bottom of the borehole to the equipment. solution recovered. Another door is air-dropped 45 tubes this is about 80% pile length. When starting to blow, compressed air is blown through pipe 45 located in the concrete pipe with a pressure of about 7kg/cm2, this pressure is kept constant. Compressed air out of pipe 45 escapes onto the pouring pipe, forming a suction pressure at the bottom of the pipe, bringing the bentonite solution and sediment along the concrete pipe to the solution filter. The rinsing process lasts 20-30s, the bentonite solution must be continuously compensated during the washing process. Then release the plumb line to measure the depth, if the bottom depth of the borehole is guaranteed (settlement 10cm), then just check the bentonite solution removed from the bottom of the borehole.

Request:

= 1.04 1.2g/cm3 (density)

=20s 30s (Viscosity)

pH=9 12 (PH)

8. Pour concrete.

After finishing blowing and washing the borehole, it is necessary to pour concrete immediately because the sand will continue to settle for a long time, affecting the quality of the piles, so the work of preparing concrete, cranes and pouring hoppers must be very smooth. . Commercial concrete used to pour piles must have a slump of 18 2cm. Concrete that is too dry or too pasty can cause blockage of pipes when pouring concrete. Concrete poured piles are poured through the concrete truck hopper, when the last concrete trucks are poured, the pressure to pour concrete is no longer great, so it is more difficult to pour concrete, to have to stuff the pipe many times and easily clog the concrete pipe.

– Concreting bored piles is pouring concrete under water, in Bentonite solution by pipe drawing method. Before pouring concrete, a cork (or foam ball) is placed in the pipe to separate the bentonite solution and the concrete solution in the pipe. Then the wick will float to the top of the pile mouth and be recovered.

– Fill the hopper with concrete, cut the rope to hang the button, the concrete pushes the wick down and spills into the bottom of the borehole. The first batch flows out through the stopper by lifting the tube 20cm from the bottom.

– Slowly lower the conduit so that it is submerged in the concrete, but it is important to ensure the movement speed of the concrete in the pipe (This speed is usually slow to prevent the concrete from stratifying v 120mm/s).

– During the concreting process, the concreting pipe is gradually withdrawn to each section so that the pipe is always submerged in the concrete mortar at least 2m. This work must be closely monitored because if there is a mistake immediately the pile will be damaged by breakage, the concrete in the pile will be discontinuous. The process of concreting piles must be continuous.

– The speed of concrete supply in the hopper must also be kept in moderation, in accordance with the speed of movement in the pipe. Not too fast to cause spillage, too slow also causes many bad consequences, the concrete flow will be interrupted.

– The time to pour concrete should be limited to only 4 hours because the first batch of concrete will be pushed to the top, so an admixture is needed to prolong the setting to ensure it does not set before the completion of the work. pile concrete. In order to ensure that foreign objects do not fall in and clog the pour pipe, a 100×100 wire mesh should be welded so that the concrete must pass through this mesh before pouring.

– To finish the concreting process, the final level of concrete must be determined. It is necessary to calculate and determine the true elevation of good quality concrete because the top part is often mixed with soil and rock. It must be taken into account that when withdrawing the concrete wall pipe, the drop due to the diameter of the drill pipe is larger than the wall pipe. If the final pile concrete is lower than the design, it is difficult and expensive to connect the piles, on the contrary, if it is too high, it is also expensive to smash many pile heads.

– At the end of the concreting process, the pipe is removed from the pile, the pipe sections are washed and placed in the specified place.

9. Withdraw the wall pipe.

– In this final stage, the supports, working platform, reinforcement anchoring to the wall pipe are removed, the wall pipe is slowly pulled up by the crane, must be pulled vertically to avoid moving the center of the pile head. A vibrating device should be attached to the bulkhead pipe to facilitate the withdrawal of the bulkhead, without causing bottlenecks at the pile end at the end of the bulkhead.

– After withdrawing the wall pipe, it is necessary to fill the hole with sand, fill the hole, collect bentonite to create a plane, temporary barrier to protect the pile. Do not vibrate in the area or drill other piles for 24 hours from the end of concreting piles within 5 times of the pile diameter (4m).

III. CHeck quality pile.

1. Causes of defects on piles.

Because bored piles are constructed in difficult conditions, although the pile construction technology is getting more and more complete, the possibility of defective piles is still quite high. A series of causes of pile damage have been synthesized and analyzed, including the following main causes:

+ Collapsing the wall during the drilling process makes the pile cross-section shrink, but just below the pile cross-section is enlarged.

+ The friction between the concrete and the support pipe is too large, the technology of pouring concrete and withdrawing the pipe is not suitable, causing the pile to be broken.

+ The borehole cleaning has not been thoroughly done, causing the drilling mud to accumulate under the pile tip, leading to a decrease in the load capacity of the pile.

+ Concrete has too low slump causing the concrete in the pile to be loose.

+ Density of reinforcement is too high so that the concrete does not leak out of the scope of the steel cage.

+ Unevenly withdrawing the support pipe causes the pile to move horizontally locally.

Research results show that the causes of damage to bored piles are quite diverse, most of the defects are caused by inappropriate construction technology. To limit these defects, it is necessary to strictly inspect all stages of pile construction.

2. Check the quality of piles during construction.

With proper construction technology and strict quality control procedures, the possibility of pile damage can be kept to a minimum. The following factors should be checked at the site:

a) Check the Bentonite solution.

The main purpose of testing Bentonite solution is to ensure that the borehole wall does not collapse during drilling as well as during concreting and to check that the bottom of the borehole is blown before concreting.

The main parameters of Bentonite solution are usually controlled as follows:

+ Sand content: < 5%

+ Density: 1.01 - 1.05

+ Viscosity: 35 sec

+ pH: 9.5 – 12

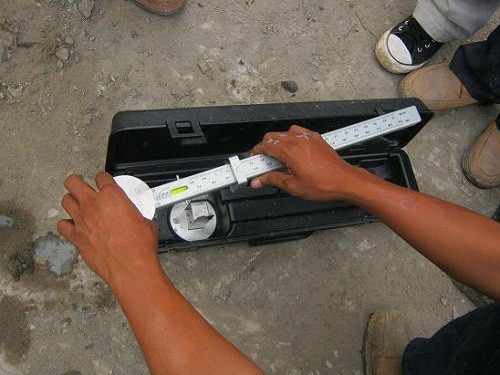

b) Check the borehole size.

After cleaning the bottom of the borehole with Bentonite solution, the following parameters of the borehole bottom should be checked:

+ Depth measurement: The bottom of the borehole is considered clean if the depth after blowing is equal to the drilling depth (determined by measuring the depth of the drill rod reached during construction or by other equipment).

+ Use some simple penetration devices to evaluate the penetration resistance of the soil at the bottom of the pit.

Measure the diameter and verticality of the borehole.

+ State of the borehole.

c) Inspect concrete before pouring.

Concrete used in the construction of bored piles usually has to check the following parameters:

+ Drop (for each dump truck): 15 cm

+ Strength after 28 days (sampling, by pop gun for concrete at the top of piles or ultrasonic): 200 kg/cm2

+ Coarse aggregate in concrete: not larger than the particle size required by technology.

+ Concrete mix level in the borehole

+ Depth of flooding of concrete pipes in concrete mix

+ Volume of concrete poured in the pile hole

The concrete to be tested for strength shall be from the mixer truck and from the pile body concrete.

d) Take notes during construction.

During the construction process, it is necessary to record the start time, end time and incidents occurring during the performance of the following jobs:

+ Put the strut.

+ Pump Bentonite solution.

+ Drill holes.

+ Blow and wash the bottom of the borehole.

+ Set the steel cage.

+ Put concrete pipe.

+ Remove the anti-tube.

+ Concrete volume for each pile.

3. Check the quality of piles after construction.

After concreting, the quality inspection of piles should be carried out to assess the quality of pile concrete at the site, detect defects and treat damaged piles.

There are several testing methods as follows:

+ Static compression method

+ Ultrasound method

+ Stress wave method: there are PIT method, PDA method.

Lethy corp

Tags search information: provide BTC . pile,supply square pile,round pile supply,larsen poles,construction kingpost shoring,foundation construction,lethycorp pile pressing, concrete pile pressing, larsen's cunt, cyes larsen, larsen eps, pressed iron piles, pressure on people's houses, bored pile drilling,