Construction process to press concrete pile by robot

1. Prepare documents related to concrete pile pressing

1.1. Personnel profile:

- Make a list of workers participating in the construction

- Health check, occupational safety training for workers participating in construction.

– Make and submit a list of employees who directly work with the Investor and related parties.

Unified form:

- Prepare and submit samples of documents and official documents used in the construction process

– Prepare and submit detailed construction progress. (attached)

1.2. Construction technical design documents:

– Continuously check all drawings applied during construction.

– Prepare and submit material samples before putting into construction.

– Prepare and submit detailed construction methods for each item on the basis of bid documents and actual conditions

site before starting construction.

2. Construction site for pressing concrete piles by robot

2.1. Temporary services

– Construction electrical system

– Construction lighting system and site protection lights

– Telephone systems and other means of communication.

- Construction water supply pipe system.

– Contractor signboard, project name plate and other dangerous sign system.

– Construct a fixed barrier system and provide enough mobile barriers and hazard lights.

2.2. Clean the ground

– Restore and protect the system of landmarks and surveyed points.

– Restore the current site, keep the current data during the construction process

– Clean, clear and sanitize the ground before conducting surveying work.

3. Construction materials and equipment

All construction equipment gathered to the site must be guaranteed operating procedures and procedures include :

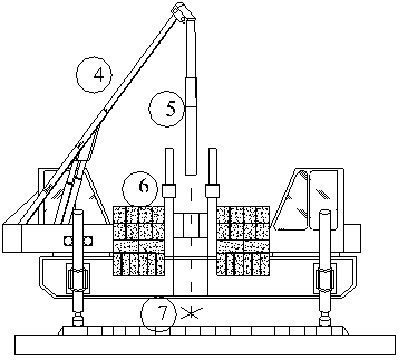

– 500T hydraulic press robot (with inspection certificate).

- Welding machine 3.

- Lighting line, theodolite or total station.

Figure 1. Robots Pile hydraulic

Figure 2. Operation of Hydraulic Piling Robot

4. Technical measures for pressing concrete piles by hydraulic press robot

4.1. Sequence of mass pressing piles

The process of pressing piles in the foundation pit includes the following steps:

a.Prepare

– Use steel bars with diameter from 8 to 10mm, length from 30 to 40cm to drive into the ground at the location heart pile to make sign.

– Construction plan, movement direction diagram of Hydraulic Pile Press Robot.

b. Pile pressing construction process:

+ Step 1: Gather concrete piles, check pile presses, get ready the necessary tools for preparation Pile concrete

+ Step 2: Crane piles from the gathering place into the press.

Figure 3. Lifting piles to the press robot

+ Step 3: Adjust the nose Concrete piles in the correct position of the determined heart, adjust the pile in the vertical direction.

Figure 4. Pile alignment

+ Step 4: Start the press and start the first press stroke.

Figure 5. Carrying out pressing

+ Step 5: Continue pressing until the end of the first pile, put the second pile in place, adjust the two ends of the pile to match and soldering.

Figure 6. Pressing the remaining pile segments

Continue pressing until the pile tip reaches the design depth.

- Stop pressing piles is applied in the following cases:

+ The pile tip reaches the design depth and the pile head pressure is not less than Pmin.

+ If the pile tip has not reached the design depth, stop pressing the pile when the pile head pressure is not less than Pmin

+ If the pile tip reaches the design level and the pile pressure is less than Pmin then pile pressing continues until the pressure reaches P .min The construction unit will notify the Supervision Consultant, the Investor, and the Design Consultant when there is a difference between the value of pressure and depth of pile pressing to have a solution, when necessary, do additional soil surveys, do test tests to have a basis for treatment conclusions.

Piles tilted beyond regulation (greater than 1%), unfinished pressed piles due to foreign objects in sand drives, abnormally hard clay seams, broken piles… all must be handled by pulling up and pressing again or adding new piles (designated by design).

Using appropriate drilling methods to destroy foreign bodies, through sand drives, hard clay seams... When the pressure has just reached the design value, the pile cannot go down anymore, while the pressure acting on the pile continues to increase beyond the design value. maximum overpressure (Pep)max then before stopping the pressure, use valve to keep the maintaining force (Pep)max within 5 minutes.In case the press does not have a retaining valve, it must be pressed three to five times with the pressure (Pmax).

c. Tolerance:

At the height of the bottom of the pile head, the error must not exceed 75mm compared to the design position, the inclination of the pile is not more than 1%. (according to TCXD 9394:2012).

d. Report on the history of pile pressing.

- The pile driving record must be recorded right during the construction process, including the following contents:

+ Date of pile casting.

+ Number of piles, location and size of piles.

+ Pile pressing depth, number of piles and pile joints.

+ Pressing device, capacity of pressing, jacking stroke, piston area, oil flow, maximum oil pump pressure.

+ Pressure to stop piling.

+ Pillar head gasket type.

+ Order of pressing piles in the group.

+ Technical problems hindering the pile driving as designed, errors in position and inclination.

+ Name of staff supervising the construction team leader.

5. Traffic management on construction site

– All operations must be easy and safe for both equipment and workers. People with no duties? operated under the rotation of the device.

- People who are not on duty are not allowed to pass through the construction area. Around the installation area of monitoring devices, there must be guidance of security personnel to avoid the influence of this equipment.

6. Pre-acceptance inspection

After completing the pile pressing of the whole project, the parties organize the inspection and acceptance at the construction site in accordance with regulations, XDCB sequence.

Records and documents include:

+ Profile quality pile.

+ Diary of pile pressing.

+ As-built drawing of piles.

+ Minutes of acceptance.

+ Other relevant documents as prescribed.

7. Troubleshooting measures

During construction, unexpected incidents may occur, the Contractor confirms to eliminate as far as possible all the risk of an accident.

– To overcome these problems well without affecting the quality and progress of the work, it is necessary to have close cooperation between the units participating in the construction and the project management agencies.

Our contractor will carry out the troubleshooting work in the following order:

- Make a record when an incident occurs.

– Preliminary assessment of the parties involved in the incident

– Request the Investor to convene relevant parties to discuss the solution and progress of troubleshooting.

- Prepare and schedule the implementation of the settlement plan according to the decision of the competent authorities.

- Implement troubleshooting.

- Evaluation, learning experience

8. Conclusion

With the available capacity and experience of a professional contractor, with a team of staff and workers who are trained and step by step trained through the construction of large projects across the country, with full capabilities complete Good works with high quality with the fastest progress and absolute safety.

Contact us

If you are in need of building or constructing a factory, please contact us to receive detailed advice and quotation. We will listen and understand your requirements and ensure the best solution.

Contact information:

- Address: No. 12, Street 27, Van Phuc Urban Area, Hiep Binh Phuoc Ward, Thu Duc City, HCMC

- Phone number: 0915.611.337 Mr. Phuong Or 0915.411.337 Mr Quan

- Email: [email protected] or [email protected]

- Website: Lethycorp.com

- Road Map: See