Construction organization and construction methods for the basement using the Larsen pile diaphragm wall and support frame system

Shoring bracing system at University of Fine Arts

I.General introduction basement construction

1.1. Content :

- Transporting basement soil

- Transportation methods are based on terrain conditions, construction sites, traffic, etc.

1.2. Construction scale and structural characteristics

- Construction site area:

- Construction area :

- Construction length, width

- Reinforce the foundation with bored piles.

- Pile connection structure with foundation plate, tie beam and reinforced concrete floor

- The diaphragm wall around the basement is made of concrete piles.

II. Organize construction sites.

2.1 General part:

- Construction organization design complies with the requirements of the bidding documents.

- Based on design drawings and other technical documents of the bidding documents.

- Based on the construction progress requirements of the bidding package.

- Based on the Contractor's capacity to provide materials, equipment and human resources.

2.2. Some comments:

- According to the construction bidding documents, the technical solution proposed is to construct diaphragm walls, barrette piles, bored piles and basement construction using the semi topdown method.

- However, through the process of studying the project's topographical and hydrogeological situation, and the influence of neighboring works, there will be flexible solutions that can use larsen piles. To ensure safety during construction work.

- Larsen sheet pile wall construction technology is considered a good solution for basement construction, fast construction, using most machines for construction. In particular, with the application of automatic pile pressing robots, the construction solution of Larsen pile diaphragm walls takes place faster and safer.

Larsen pile pressing robot

2.3.Proposed technical solution:

-Larsen piles are built to the design elevation so that the pile tip elevation is +0.5m compared to the natural elevation.

- Excavation to a depth of -0.5m to install the H-shaped steel belt frame

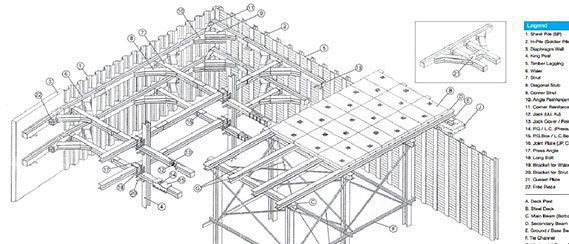

-Continue to install the Shoring-Kingpost anti-frame system.

- Excavation and transport of soil out to the construction level of the bottom concrete layer.

-Can be constructed using the rolling method for large construction areas.

III. DETAILED CONSTRUCTION MEASURES

3.1. Comply with technical standards:

-Regulations on quality management of construction works TCVN ND – 209/2004/NDSD – CP

-Basic principles of quality management of construction works TCVN 5637 – 1991

-Organizing construction of TCVN 5055 – 1985

-Tolerances in construction works - measurement and inspection methods for works and prefabricated components of works, location of measurement points TC 210 - 1998

- System of labor safety standards. Basic regulations TCVN 2287 – 1978

-Electrical safety in construction, general requirements TCVN 4086 – 1985

-Electrical welding work requires general safety requirements TCVN 3146 – 1986

- Technical regulations on safety of lifting equipment TCVN 4244 – 1986

- Technical safety regulations in construction TCVN 5308 – 1991

-Fire and explosion prevention for houses and structures TCVN 2622 – 1995

3.2. Site positioning and foundation excavation work:

3.2.1. Construction surveying work

- Surveying plays a very important role, it helps the construction to accurately shape and size the building's geometry, ensure verticality, structural tilt, and determine the correct position. The location of the center axis of the works, of the components, technical systems, and pipes, minimizes errors in construction work. Surveying work must comply with TCVN 3972-85.

- Positioning the project: After receiving the handover from Party A of the site, landmarks and elevation of the area. Based on the positioning plan drawing, take measurements by machine.

- Determine the location and elevation ± 0.000 of the construction items based on the total area of the area, then make a written confirmation with the Project Management Board on the basis that the designer is responsible for the technical solution. position technique, height ± 0.000. Locate the project within the land area according to the design.

- Establish a construction control network as a means for all survey work. Proceed to set monitoring markers for the project. These observations are intended to monitor the impact of the construction process on the deformation of the project itself.

- Monitoring landmarks and monitoring equipment must be strictly protected and managed, and use on the project must be approved by the investor. Measuring equipment must be calibrated and calibrated within the allowable period of use.

- The project must have at least 2 main marker piles, with the marker piles at least 3 meters away from the edge of the structure. When constructing, based on landmark piles, make detailed measurements of the house's positioning axes.

- Prepare records of monitoring milestones and regular monitoring reports for each stage of construction to monitor deformation and position deviations and promptly find solutions.

3.2.2. Lasen pile construction work

- Use Larsen piles to make a surrounding wall, then level the ground to create a level surface

service for pile construction. After the construction of piles and retaining walls is completed, the piles will be pulled up for reuse.

Preparation

a. Electricity supply:

Complete installation of 380V - 125KW power source and temporary road for construction machines and cranes.

b. Estimated construction time

- For pile pressing method using static machine, working time is from 6:00 a.m. to 11:00 p.m.

- For pile pressing method with vibrating hammer, working time is from 7:00 a.m. to 7:00 p.m.

c.Construction organization

Method for pressing and withdrawing Larsen IV piles using static pressing method:

- Gather Larsen presses, cranes and pile materials to the construction site.

- Construction equipment includes:

- Specialized tire crane:

- Brand: Kato 25 tons

- Lifting Capacity: 25 tons.

- Country of manufacture: Japan

- Static pile press: AVP- 130

- Pile head pressure: 70 tons 130 tons

- Country of manufacture: Japan.

- Power source: 380V – 50KW.

Construction:

-Use 1 to 2 hydraulic pile presses (with the above parameters) to construct the construction method drawing and the crane to serve pressing piles to move on the temporary road.

- Due to alternating construction work, we have to arrange it smoothly to avoid construction affecting each other, leading to slow progress.

- The verticality of Larsen piles has an error in the range of 0-1% and the pile tip tilts towards the outside of the building. The verticality of the pile during the pressing process is adjusted by machine, using a beam to determine the verticality of the pile.

- Sheet pile wall construction process:

Step 1: Press the first pile bar to the specified depth.

Step 2: Press the second pile bar and determine the load capacity of the pile.

Step 3: Raise the machine body and stop at the position of the pile clamp lower than the pile head.

Step 4: After stabilizing, raise the pile press machine.

Step 5: Push the hammer head pile clamp forward and rotate the clamp from right to left.

Step 6: Adjust the hammer head to the pile to slowly lower the pile.

- Note that the pressing part must be carefully aligned so that the pile does not become skewed.

Larsen Shoring model

In case of deposit withdrawal:

- When withdrawing piles for pressing, then the location of the crane to serve the extraction will be discussed with the investor. If it is not possible to stand on the internal road and ring road, the investor must give permission. The construction party brought the crane down to the basement floor to serve the pile removal work.

- Our construction unit proposed: In order to be able to withdraw the piles smoothly, it is recommended that the Investor will dig and construct the tunnel wall, then withdraw the piles and then continue constructing the bottom floor of the basement. (To avoid the situation where the crane has to move into the basement floor and damage the floor)

3.2.3. Excavation of foundation holes

- Dig a foundation hole with an excavator, then use a tower crane to scoop and load the soil onto a truck to transport it to the place where the Contractor has determined it is allowed to dump.

The Contractor plans to mobilize a sufficient number of workers and vehicles to transport the excavated soil so that there are no traffic jams. Wherever the volume of excavated soil is transported there, it will not affect the construction. next jobs. The contractor prepares the construction plan according to the following process: - Soil compaction, brick construction, formwork construction, floor beam structure construction, reinforcement +0,000

- Excavating soil for basement 1 manually, combined with a tower crane to load soil onto transport trucks and dump it

- Construction of +0,000 reinforced basement floor and reinforced floor (measured floor) sequentially from top to bottom (basement wall panels 1, at the location of the wall supporting floor beams, construct before the remaining wall panels. later), with attached drawings

- Compacting the ground, building bricks and formwork, constructing the first floor beam structure and reinforcement

- Digging the basement soil manually, combined with a tower crane to load the soil onto a transport truck and dump it

- Pouring concrete for foundation lining, erecting formwork, constructing core foundation structure

- Fabrication and erection of formwork, erection of steel reinforcement and construction of basement floor beam structures in order from bottom to top.

- In this bidding package, our Contractor is very interested in the foundation pit water collection system. The Contractor's solution is that while constructing each basement floor, he must always create temporary sump pits. At the same time, there is someone on duty using a sufficient number of pumps to pump water into the area's general drainage system (drawings attached).

3.2.4. The work of completing, accepting and handing over the project complies with and applies:

- Technical standards for construction and acceptance

- Rules for construction and acceptance of soil work TCVN 447-1987

- Rules for acceptance of construction site completion TCVN 4516 – 1988

- Rules for construction and acceptance of completed works TCVN 5674 - 1992

Construction of basement with Larsen piles combined with Shoring kingpost system

Supply and construction of concrete pile driving DUL D500, D800, D1000...